INCREASE SPEED, QUALITY & PROFITABILITY WITH COLORDRY XL3000

Case Study: The Advantage & Benefits of adding a single Final Flexo Dryer (FFD)

Discover how JB Machinery’s ColorDry® XL3000 can revolutionize your printing operations by enhancing speed, quality, and profitability.

Customer Challenge

Overcoming Production Hurdles

Our client, a major corrugated converter, faced significant obstacles in maintaining optimal production speeds. Slow ink drying times on kraft and mottled stock led to frequent halts in production. Additionally, ink transferred to the anvil cover caused frequent downtime, while color dullness and marking through transfer and die cut sections hindered the quality of the final product. The inability to efficiently process premium semi-coated sheets further restricted their operational capabilities.

These challenges not only reduced press uptime but also limited productivity and prevented the company from capitalizing on premium job opportunities. The need for a reliable solution to enhance production efficiency and print quality was paramount.

Challenges:

- Slow production speeds on kraft and mottled stock due to slow ink dry times

- Frequent downtime caused by ink transfer to the anvil cover

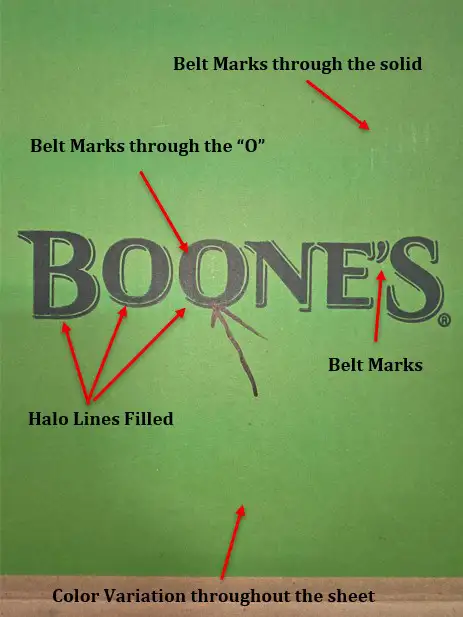

- Color dullness and marking through transfer and die cut sections

- Limited ability to run premium semi-coated sheets efficiently

The Solution:

JB Machinery ColorDry® XL3000 IR Dryers

ColorDry® XL3000 IR Dryers is the cutting-edge solution designed to tackle the pressing challenges faced by our client. This advanced system seamlessly integrates with rotary die cutters and flexo lines to deliver consistent, high-efficiency ink curing across all board types.

Key Capabilities

- Rapid drying on full or spot coverage

- Automatic energy optimization for lower power consumption

- Eliminates ink transfer and ghosting issues

- Compatible with water-based and hybrid inks

- Enhances color brilliance, gloss & dry trapping

The Results:

Double Production Speed

Run rates doubled on kraft and mottled stock—maintaining color density and die cutting in a single pass.

Maximum Uptime

No ink transfer to anvil covers, fewer stoppages, and cleaner operation throughout the line.

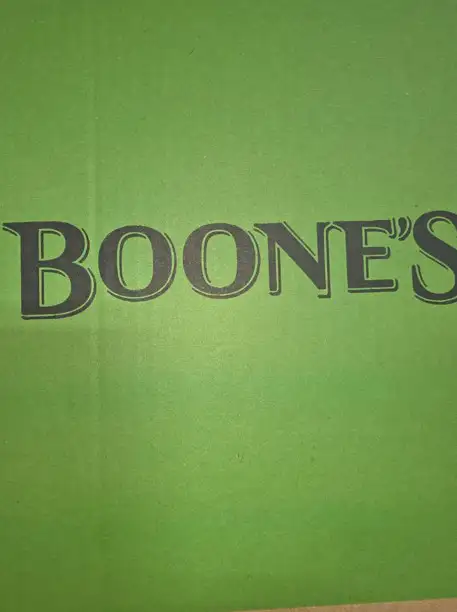

Enhanced Print Quality

Brighter, more vibrant colors. Eliminated ghosting and marking. Achieved high gloss levels and improved ink stability.

Reduced Waste & Increased Capacity

High hold-out substrates now print, die cut, and finish in one pass, minimizing rejects and enabling more production time per shift.

Remarkable Production Gains

Customer Impact

Before the installation of the ColorDry® XL3000, operations were plagued by frequent stoppages and inconsistent color output, resulting in slower production speeds. Post-installation, the transformation was remarkable: throughput doubled, color consistency was flawless, and downtime was nearly eliminated. This shift not only improved operational efficiency but also opened up new opportunities for premium jobs, showcasing the profound impact of the ColorDry® XL3000 on customer operations.

Before:

- frequent stoppages

- inconsistent color

- slower speeds

After:

- double throughput

- flawless color

- near-zero downtime

Before and After Results:

The installation of the ColorDry® XL3000 has revolutionized customer operations, turning challenges into opportunities. With enhanced print quality and increased production speeds, customers are now able to meet higher demands with ease. The system’s ability to maintain color density and reduce waste has led to a more sustainable and profitable workflow, embodying JB Machinery’s commitment to excellence.